How digital twins and VR will help build a better tomorrow?

Do you know that by 2026, the global market value for digital twinning will be $48.2 billion?

According to a statement released by Paul Smetanin, President of the Canadian Centre for Economic Analysis.

The discussion of digital twins and Virtual Reality might not be a new exciting topic, but this piece of observation will reveal a new perspective on its application.

As stated in Daily Commercial News.

Creativity in architecture extends beyond aesthetics to address functionality and sustainability. Technology and tools are being used to enhance the field of architecture today.

Many of the chief architectural innovations in history were due to engineering and mathematical breakthroughs, including vaults, aqueducts, and classical columns. With every new invention, design barriers shifted one step higher; pushing the succeeding generations to explore more.

From the development of reinforced concrete and steel to the development of contemporary technology, every generation has been fortunate to witness such advancements. Architecture flourishes as a common ground tying up various disciplines, namely computer science, engineering and environmental science.

Speaking of technological developments and their repercussions in the construction field, let’s deep dive into the recently booming subjects digital twins and VR.

The Power of Digital Twins

In this age of advanced technology, almost everything has become practically possible. As we strive towards an efficient future, we are reimagining the possibilities of visualization. Although rigorous design processes and detailed planning are considered being at the forefront of any structural development, close to real-time digital representations weigh higher attention.

On that note, Digital Twin has been brought into the limelight, and industry experts who realized the true potential of its application are reaching new heights.

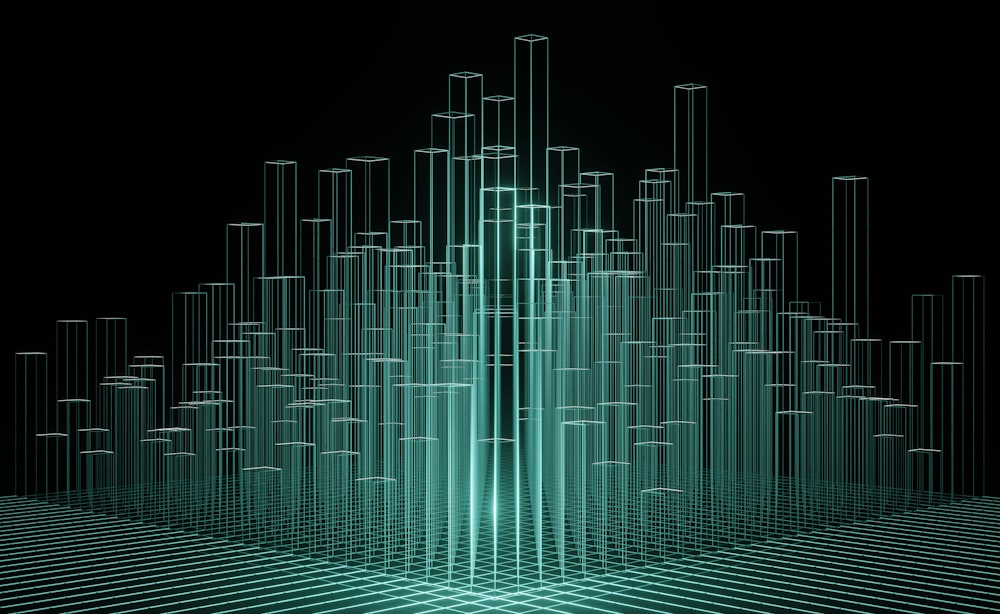

Digital twin – as one may presume, is not a mere latest technology but is a powerful tool with which AEC firms are exploring new ventures. It is as flexible as it could be applied to any physical entity, be it a 3D product or a city planning. Digital twins, in other words, represent the exact digital replica of the original design. Only that it exactly replicates the dynamic character of the design.

When considered in terms of the AEC industry, it will replicate the nooks and corners of the physical structure, making it easily accessible for future reference. Imagine you could figure out if there’s an issue in the MEP system of a building by just referring to the digital twin of it from the comfort of staying at home/office.

VR and Digital Twins – A Comparison

Because of its built-in acting capabilities, virtual reality (VR) is a well-suited tool for facilitating human interaction with CPPS (Construction Phase Plans). Virtual reality does, in fact, provide lifelike rendering, intuitive gesture interactions, collaborative features, comprehensive 3D scale-one visualization, and fast navigation tools in a large area. As a result, it makes it simple for users to concentrate on each system component—from the smallest to the entire factory.

Meanwhile, digital twins in the AEC industry enable firms and owners to minimize conflicts by providing data-rich assets throughout the design and operation process. It guides the professionals to access and keep track of data during their planning stage and act as a reference material after it is occupied by the users.

Real-World Use of VR & Digital Twins

Now that we are aware of the potential and characteristics of digital twins and VR, let’s interpret the way they’re applied in various sectors of the AEC industry. VR and digital twin technology can be applied at any scale ranging from residential to urban planning, rather than merely at a selective scale.

Adaptive Reuse

The indestructible combination of VR and digital twin has elevated the construction industry to a new height from restoring old structures to designing new ones. Regarding VR, it uses an advanced tool called photogrammetry to scan the existing physical entity with exact features and scale.

This process can be implemented in adaptive reuse projects, where it can be used to perceive the characteristics of the depleted structure and how exactly it can be remodeled to meet the new requirements. Not only that, it allows you to document any historical structure without any disruption.

Efficient Project Management

1. Bringing Down Coasts

Planning, designing and constructing a building is an extensive process, where every step takes time and ample amount of effort to be executed. On that note, when you’re able to perceive real-time data and plan a few details beforehand, you can cut down both the budget and time. With digital twins, you can replicate and observe the entire process without fabricating the actual design.

With precise cost estimations and maintaining your cost limit at every stage, digital twins can boost your project’s timeline.

2. Optimize Utilization

With increased accounting of remote work culture, digital twin allows users to collaborate effortlessly whilst managing complex work schedules. It can increase the efficiency of workflow by allowing the team members to access real-time data and saving ample time.

For instance, if a building designed with the help of a digital twin is about to face an issue in its HVAC system. The real-time data that digital twin has been monitoring gives you an indication that an air filter or any part has to be changed. At the end of the day, the more you feed into the database, the more we will benefit out of it.

3. Effective Functioning

Besides the aforementioned aspects, adopting digital twins paves the way to advanced collaborations and lets you prioritize the type of data you actually require. Irrespective of the size of a team, it allows sharing and work on the saved data.

A digital twin allows workers to detect issues instantly, allowing solutions to be implemented quickly and reducing costly delays caused by faulty shipments or bad weather.

CASE STUDY

Digital Twin Example in Construction- Canada Line SkyTrain in Vancouver, Canada

The Canada Line, operational since 2009, has embraced new technologies to enhance daily operations. An accurate real-world model of the line has been created for operators using LiDAR scans as part of the digital twin initiative. Subsequently, sensors were attached to crucial assets like switches to continuously update the digital twin with real-time data.

Sensors were installed on certain switches identified as ‘golden assets’ essential to meeting performance targets. This data accumulation over time establishes a baseline for normal switch behavior.

Any deviation from this norm triggers alerts for operators, enabling them to proactively create maintenance plans and prevent downtime. This shift towards data-driven decision-making has already proven effective, significantly improving the overall performance of the Canada Line.

Elevating Beyond Boundaries

As architects and designers, we have the responsibility of building a better and efficient future. Moreover, we embrace a future in which distances diminish, problems become puzzles waiting for solutions, and our collective dreams shape the reality of the next generation.

While we go to work every day and work mundanely on the same software, there is some innovation happening in the background. Tomorrow beckons, and with digital twins and VR as our guides, we shall embark on a journey towards a future redefined.

Join our Newsletter

Get our best content on Architecture, Creative Strategies and Business. Delivered each week for free.

JOIN THE

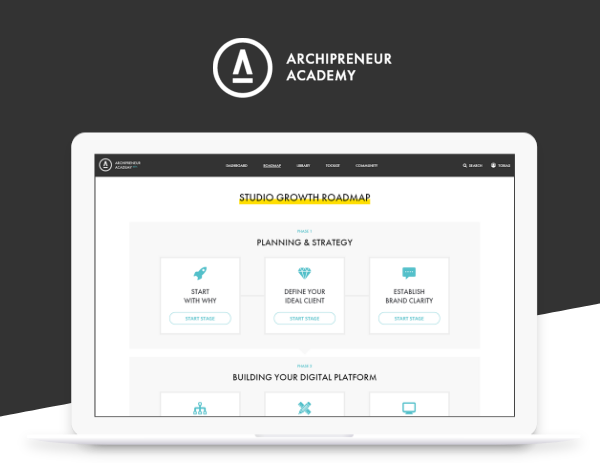

ARCHIPRENEUR ACADEMY

- 9 Stage Studio Growth Roadmap

- Library of In-Depth Courses

- Checklists and Workbooks

- Quick Tips and Tutorials

- A Supportive Online Community