How Will 3D Printing Transform the A/E/C Industry?

As 3D printers have become more affordable, so have a myriad of startups worldwide made use of the rapidly evolving industry. New materials, manufacturing techniques, ambitious prototypes and open-source designs constantly push the envelope for today’s manufacturing solutions, but is 3D technology really destined to revamp the A/E/C industry?

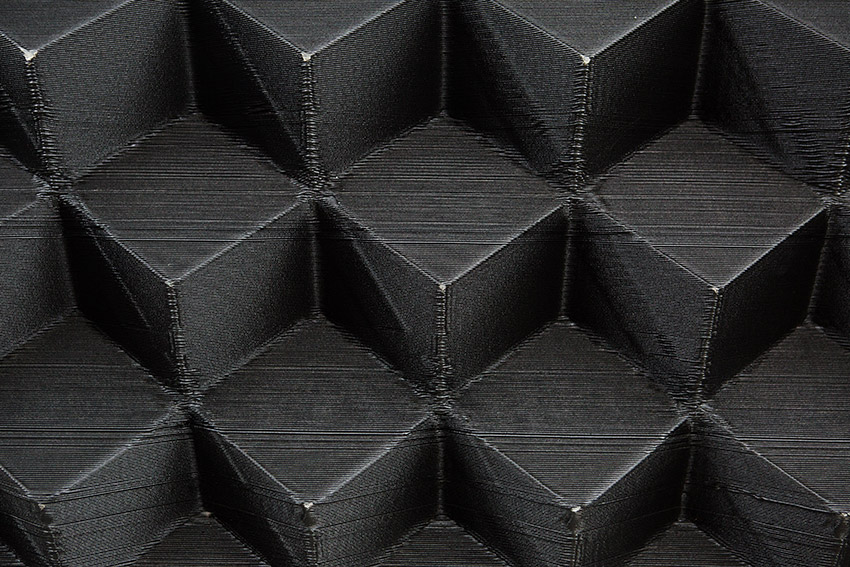

3D printing, or “additive manufacturing” is a process of making objects from digital models by gradually layering materials over each other to create a replica of the digital original. The technology has existed since the 1980s but, until recently, has mostly been used by large companies for rapid prototyping.

Its recent proliferation has brought the technology’s potential, or at least glimmers of it, to consumers and professionals outside the large conglomerates, stirring excitement in entrepreneurs looking to get a foothold in the A/E/C industry. Some say that the hype surrounding 3D printing has not yet been justified by any concrete successes, while others swear that the technology has the potential to become a significant tour de force in the cultural and business sectors.

Over the last ten years, 3D printers have become much more affordable for small businesses and entrepreneurs, and there now number over 200 startups worldwide that figure 3D printing in their work. Some use 3D printing to create product components, while others create products entirely from 3D printing tools. The technology’s ability to economize production time and create prototypes as well as individual parts of a product are the major reasons for the skyrocketing number of keen investors.

If we look beyond the possibility of 3D printed belt buckles, toys, smartphone cases and other trinkets, there are complex issues surrounding 3D printing. Undoubtedly, the world has never before seen a technology that has been able to translate our ideas into tangible objects with such ease and efficiency. Yet 3D printing is still in its infancy and due caution is advised for utilizing it over the next decade of its development. Discretion may be particularly necessary for archipreneurs, who are some of the most likely users of this new technology in their business pursuits.

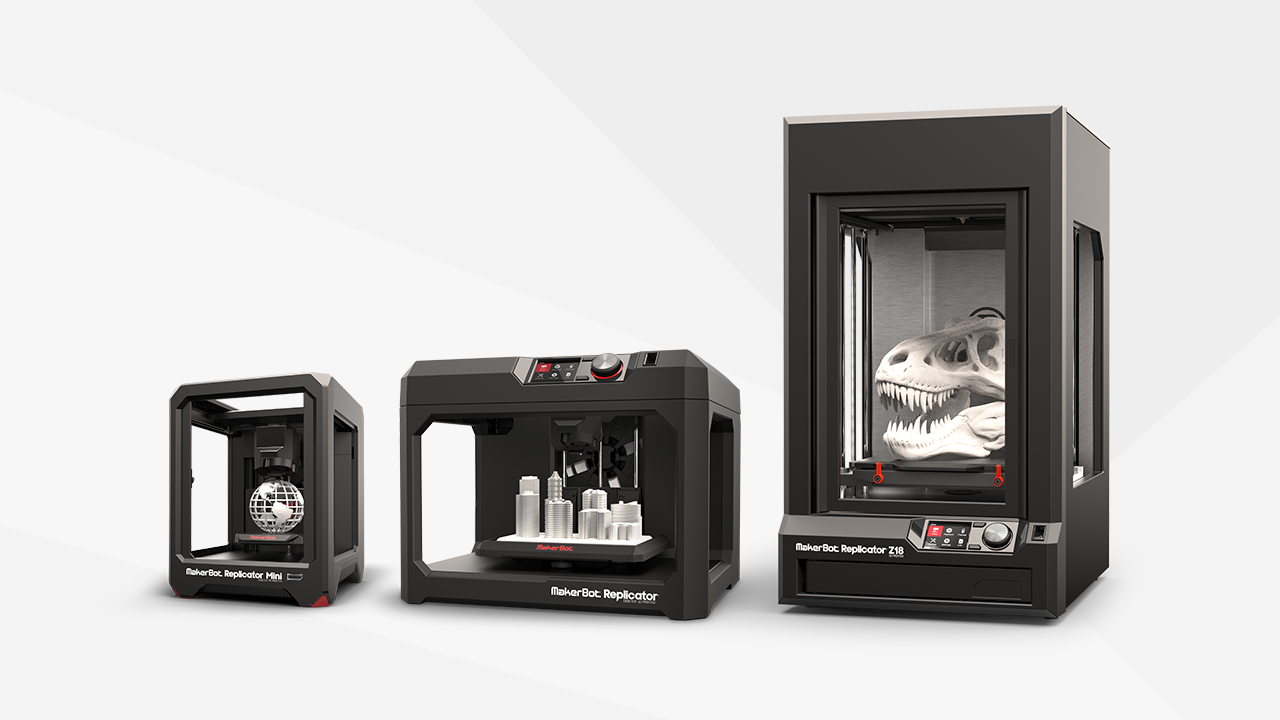

While 3D printing offers solutions for creating complex objects, the technology remains hindered by cost and scale. Consumer-type 3D printers are still too expensive for the average buyer, with costs rising exponentially with printer sizes. These high costs are having a knock-on effect for companies that are making and selling 3D printers.

Earlier this year, 3D printing pioneer MakerBot had to close several of its retail shops and lay off 20 percent of its staff. The company, founded in 2009, initially had a period of rapid growth but had to downsize after falling short of its financial targets in 2014. MakerBot’s decline proves that although the future of 3D printing seems bright when looking at the potential of the technology itself, a lot of groundwork has to be laid for it to be a viable financial solution for smaller companies.

For 3D printing to be adopted across the architectural industry, there has to be an entrepreneurial environment for companies trying to overcome the current limitations of the technology and broaden its use through new business models. When it comes to architecture, 3D printing hasn’t yet made much of an impact. It is reasonable to assume that the technology will need to reach a certain level of maturity before it’s implemented in any viable way.

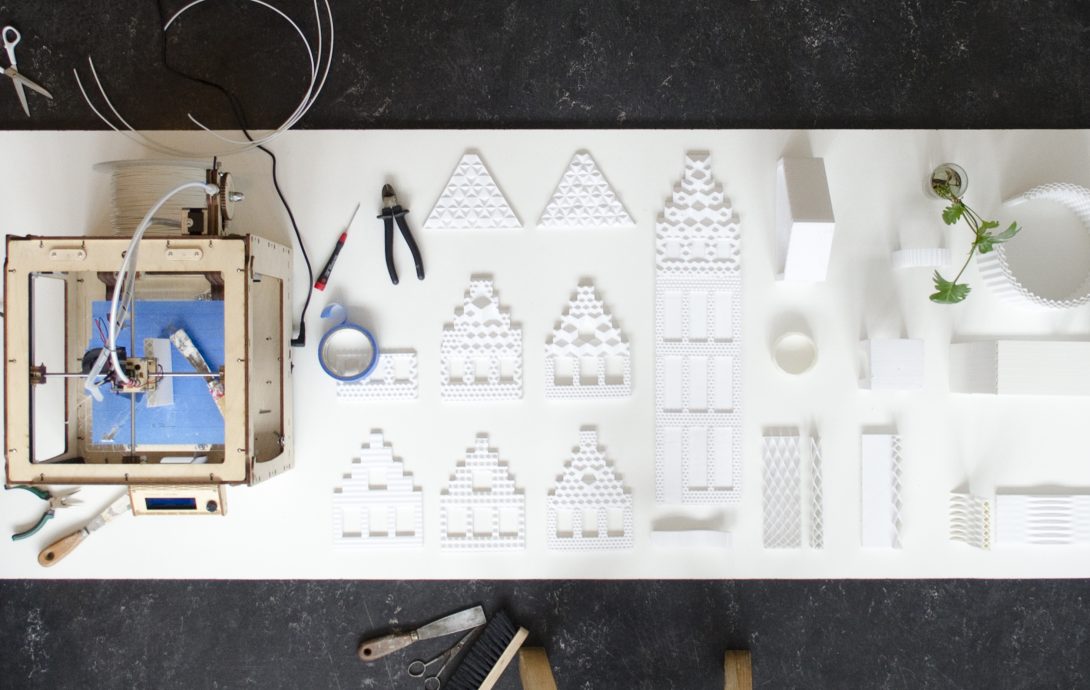

Having said that, there are several examples of young architects who are experimenting with 3D printing. Dutch firm Dus is working on a project called Canal House, with the goal to 3D print an entire house. The architects at Dus plan to use a purpose-built printer called the KamerMaker and 3D print the house on-site. They will test print each component at a scale of 1:20 before switching to a 1:1 scale.

3D printing technology also plays a significant part in new building construction trends. One of the most advanced examples of this is a project by Behrokh Khoshnevis, who built a computer-controlled injection system that pours concrete according to a pre-loaded set of blueprints. The machine has two crane-like arms and a crossbeam that carries the printhead. The entire machine runs along a set of tracks and can work on all parts of the house simultaneously, in a process called “contour crafting”.

Contour crafting technology has great potential for automating the construction of entire structures as well as their sub-components, and its development could make a significant impact on the construction industry by reducing manual labor and speeding up the building process.

The largest printer in the world, D-Shape, was built by Enrico Dini and stacks layers of sand and binding materials to make instant sandstone that, according to Dini, requires no steel reinforcements and is more durable than concrete. The European Space Agency is testing D-Shape for building their lunar bases, and architect Adam Kushner has received the go-ahead to use D-Shape for 3D printing an entire estate in upstate New York.

Despite these promising developments, we are still far from implementing 3D printing in the A/E/C industry in a systemic, financially viable way. It is more probable that the technology will first have to revolutionize the way that smaller objects are manufactured. The potential to customize objects through 3D printing is vast, although most enterprises currently only use it to prototype objects.

A/E/C professionals remain skeptical about the idea of scaling up 3D printing technology, which has so far only been used to make small objects. Even so, those working on the possibility of 3D printing entire houses and housing blocks are convinced that additive manufacturing will transform the industry.

Join our Newsletter

Get our best content on Architecture, Creative Strategies and Business. Delivered each week for free.

JOIN THE

ARCHIPRENEUR ACADEMY

- 9 Stage Studio Growth Roadmap

- Library of In-Depth Courses

- Checklists and Workbooks

- Quick Tips and Tutorials

- A Supportive Online Community